CNC Machining

aluminum precision products

Our capabilities include turning, milling, drilling, and advanced 5-axis CNC machining aluminum,

ensuring complex geometries are produced with accuracy and consistency.

We Are Your Trusted Aluminum Parts Machining Supplier

As a professional CNC machining factory, we specialize in producing high-quality aluminum parts with precision, durability, and excellent surface finishes. With advanced equipment and skilled engineers, we are able to handle a wide range of aluminum CNC machining processes, from prototypes to large-scale production. Whether you need custom aluminum components, CNC machined aluminum parts, or complex structures, we deliver reliable solutions tailored to your needs.

HRC Custom Aluminum Products

Aluminum itself is a lightweight, strong, and corrosion-resistant material. When combined with CNC machining, these qualities are maximized, resulting in durable and high-performance parts. The process is also highly efficient, enabling fast production times and consistent quality across large batches. Finally, CNC-machined parts are ready for various surface treatments, like anodizing, to enhance both their performance and appearance.

Aluminum cycle gear

Bicycle gears are core transmission components, precision-machined from high-strength alloys with optimized tooth profiles. They adapt to different road conditions via shifting, offering durability and lightweight design for a smooth, energy-saving ride.

diving flashlight shell

Precision CNC-machined aluminum-shell for diving flashlights, offering lightweight strength, corrosion resistance, and superior heat dissipation. Perfect for durable, waterproof, and high-performance lighting housings.

test tube heat block

CNC-machined aluminum laboratory test tube heating block with excellent thermal conductivity, durability, and precision. You can ensures uniform heating, corrosion resistance, and reliable performance for lab applications.

Aluminum Shift Knob

Upgrade your ride with a premium aluminum shift knob. Made from durable and lightweight aluminum, it provides a solid, comfortable feel and a modern look. It's a simple, universal upgrade for any car.

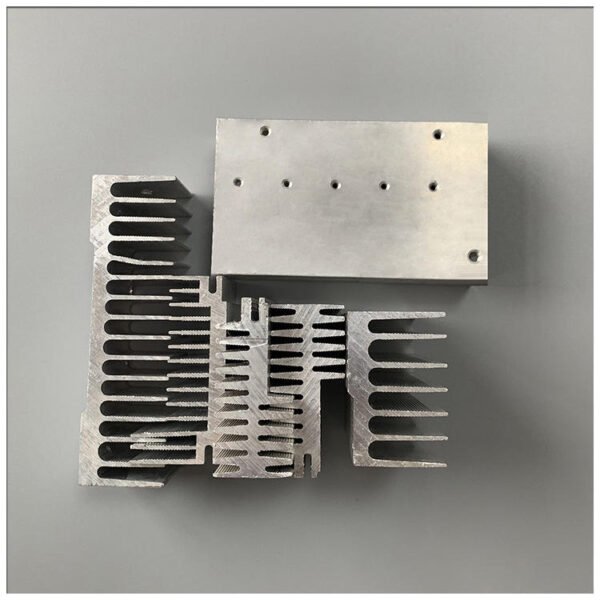

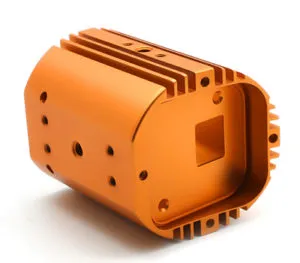

Aluminum Heat Sink

High-performance aluminum heat sink with excellent thermal conductivity, lightweight design, and corrosion resistance—ideal for efficient cooling in electronics, LED, and industrial applications.

Aluminum Snus Can

Durable snus can with a sleek, compact design for easy carrying. Keeps snus fresh and secure, perfect for daily use, travel, or outdoor activities. It is stylish and practical, easy to carry and store on the go.

Benefits of CNC Machined Aluminum Parts

CNC machined aluminum parts offer a wide range of advantages over other materials and processes.

Precision and Consistency

Aluminum CNC machining parts are produced with advanced milling, turning, and drilling equipment, ensuring precise shapes and high dimensional accuracy.

Versatility in Applications

From aluminum CNC turning parts to custom aluminum parts, these components are suitable for industries that demand both functional and aesthetic performance.

Cost-Effective Manufacturing

Aluminum machining is faster and more affordable compared to many alternative materials, making it ideal for both custom CNC aluminum parts and bulk aluminum products wholesale.

Lightweight with High Strength

CNC aluminum machining parts provide strength comparable to heavier metals but at a fraction of the weight, helping reduce costs in transportation and fuel consumption.

Aluminum Materials Commonly Used in CNC Machining

Choosing the right aluminum alloy is crucial for achieving the desired performance in CNC machining, as each grade offers unique properties—from strength and corrosion resistance to machinability and weldability—tailored to specific applications. Selecting the optimal alloy not only ensures the final part meets functional requirements but also enhances machining efficiency, reduces production costs, and extends the product’s service life, making it a critical decision in the manufacturing process.

| Item | Materials | Description |

|---|---|---|

| 1 | 6061 Aluminum | Ideal for structural and general-purpose CNC aluminum parts, 6061 aluminum boasts excellent machinability, weldability, and moderate strength, making it a top choice for brackets, frames, and industrial components. |

| 2 | 7075 Aluminum | Used for aerospace-grade custom aluminum products requiring high strength, 7075 aluminum delivers superior tensile strength and fatigue resistance, perfect for aircraft parts, high-stress gears, and precision tools. |

| 3 | 5052 Aluminum | Popular for corrosion-resistant aluminum CNC machining parts, especially in marine environments, 5052 aluminum offers exceptional resistance to saltwater and humidity, ideal for boat fittings, fuel tanks, and outdoor hardware. |

| 4 | 6082 Aluminum | Frequently applied in heavy-duty aluminum parts manufacturing for automotive and machinery, 6082 aluminum provides high strength-to-weight ratio and good formability, suitable for truck frames, hydraulic components, and structural supports. |

| 5 | 2024 Aluminum | A go-to for high-strength aluminum CNC parts in aerospace and defense, 2024 aluminum features excellent fatigue resistance and machinability, commonly used in aircraft wings, structural fittings, and high-performance components. |

| 6 | 3003 Aluminum | Preferred for lightweight, corrosion-resistant aluminum machining projects, 3003 aluminum offers good weldability and formability, making it ideal for heat exchangers, cookware, and decorative trim pieces. |

The types of CNC machine tools

CNC machining for aluminum products uses computer-controlled tools to shape aluminum into precise parts. Common processes include milling (for cutting complex 3D shapes), turning (for cylindrical components like shafts), drilling (to create holes), and tapping (for internal threads). Aluminum’s low density and good machinability let these processes run efficiently, with high precision (often to ±0.001 inches) and smooth surface finishes.

CNC Milling

CNC milling produces complex geometries and flat surfaces, making it one of the most common methods for aluminum CNC parts.

CNC Turning

Aluminum CNC turning parts are manufactured by rotating the workpiece, ideal for shafts, connectors, and round components.

CNC Drilling

Creates accurate holes and openings, an essential step in custom CNC aluminum parts production.

CNC Tapping

CNC tapping is a computer-controlled process that cuts precise internal threads in pre-drilled holes for secure fastener connections.

The methods of CNC Processing aluminum products

CNC machine tools are classified according to their degrees of freedom of motion, that is, the number of coordinate axes on which the machine tool can perform simultaneous interpolation.

3-Axis CNC Machining

3-axis CNC machining is a fundamental and widely used subtractive manufacturing process. In this system, the cutting tool operates along three linear axes of motion: the X-axis (left to right), the Y-axis (front to back), and the Z-axis (up and down). The workpiece remains fixed in a single position on the machine table throughout the entire operation. This setup is excellent for machining parts with relatively simple geometries, such as milling pockets, drilling holes, and cutting sharp contours. While it is highly reliable, cost-effective, and capable of producing components with excellent accuracy, its primary limitation is that it cannot easily machine features on the sides or undercuts of a part without manual repositioning, which interrupts the workflow and can introduce alignment errors.

4-Axis CNC Machining

4-axis CNC machining introduces a significant advancement by adding a rotational axis, typically designated as the A-axis, which allows the workpiece to rotate automatically around the X-axis. This rotary movement enables the machine to access four sides of the part in a single, continuous setup. This capability is indispensable for machining complex contours, engraving on cylindrical surfaces, and producing parts with features that are not perpendicular to a single plane, such as camshafts or helical gears. The key advantages of 4-axis machining include reduced setup time, improved accuracy by eliminating the need for manual repositioning, and the ability to create more intricate and uniform geometries that would be inefficient or impossible to produce on a 3-axis machine.

5-Axis CNC Machining

5-axis CNC machining fulfills demands for high-accuracy aluminum parts with complex geometries. The workpiece can be processed in multiple directions along with cutting in five angles of the axes simultaneously. Our advanced 5-axis CNC machines make it possible to complete all styles of aluminum milling tasks that require machined parts with extreme precision and complex shapes.

Efficiency

One single setup helps to save setup time, fasten the lead time, and increase productivity.

Intricate geometry

5-axis CNC machines with versatile configurations allow for the complex geometry of aluminum parts.

Higher accuracy & tolerance

Workpieces can be machined in a single run, thus quality is improved while error is reduced.

Higher spindle speeds and feed rates

The load on the cutting tool can be reduced by the use of more rigid and shorter tools.

One-Stop Custom Manufacturing Solution

We specialize in aluminum parts manufacturing with the capability to handle both low-volume custom CNC aluminum parts and large-scale aluminum production. With advanced CNC machines, we ensure efficiency and speed without compromising accuracy. Our team also emphasizes sustainable aluminum production to meet modern industry standards.

Surface Finishes for CNC Aluminum Products

Surface treatment is essential to improve the durability, corrosion resistance, and appearance of aluminum parts. It also allows the addition of colors and finishes tailored to brand and function.

Anodizing

An electrochemical process that thickens the natural oxide layer on aluminum parts, creating an extremely hard, durable, and corrosion-resistant finish.

- Wide color options

- Electrical insulation

- Increased surface hardness

- Excellent corrosion resistance

- Type II (standard) and Type III (hard coat)

Sandblasting

Precisely propels fine media at high pressure to deeply clean and evenly texture the surface, effectively removing stubborn tool marks and creating a smooth, uniform matte finish.

- Various grit sizes available

- Uniform matte surface finish

- Works with multiple materials

- Effective for paint preparation

- Removes tool marks and blemishes

Electroplating

Uses a precise electrical current to deposit a thin protective layer of metal to enhance appearance, provide corrosion resistance, and increase surface hardness.

- Decorative appearance

- Improved surface hardness

- Better electrical conductivity

- Enhanced corrosion resistance

- Zinc, nickel, chrome, and gold options

Brushed Finish

A mechanical process that creates a uniform surface texture with fine, directional grains for a distinctive aesthetic look.

- Directional satin finish

- Consistent grain pattern

- Available on most metals

- Enhanced aesthetic appeal

- Hides fingerprints and minor scratches

Powder Coating

A dry finishing process that creates a thick, durable, and attractive coating highly resistant to chipping, scratching, and fading.

- Uniform thickness

- Extremely durable finish

- Resistant to chips and scratches

- Environmentally friendly process

- Wide range of colors and textures

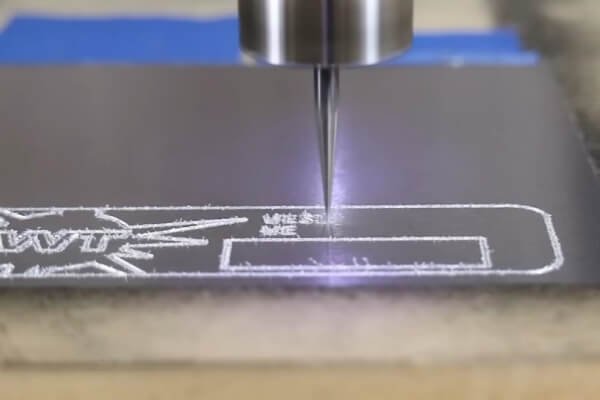

Laser Engraving

Uses a high-powered laser beam to precisely etch or mark the surface, ideal for adding permanent serial numbers, barcodes, and logos.

- Fast turnaround

- No tooling costs

- Permanent markings

- Works on most materials

- High precision and accuracy

Ensuring Quality Aluminum Products

Our strict inspection standards guarantee that every CNC machining aluminum part meets international quality benchmarks. We focus on producing aluminum precision products that align with demanding industry requirements. By combining advanced equipment with skilled engineering, we deliver consistent, quality aluminum products for our global customers.

Applications of Aluminum CNC Machining Products

CNC aluminum parts are critical in a wide range of industries:

Aerospace – CNC machining aluminum parts reduce weight without sacrificing strength.

Automotive – Custom aluminum products improve performance and efficiency.

Electronics – Aluminum CNC parts act as housings, connectors, and heat sinks.

Consumer Products – From laptops to sporting equipment, polished CNC aluminum parts provide durability and style.

In addition, we also support aluminum products wholesale, giving businesses access to reliable and cost-effective supply for different application needs.

Put your parts into production today

- All information and uploads are secure and confidential.