Precision CNC Machining Services

We specialize in CNC machining for aluminum, steel, and complex custom parts with tight tolerances and fast turnaround.

Huaruicheng Metal Manufacturing

- TOP 10 Metal Manufacturer in China

HRC is a trusted manufacturer specializing in CNC machining services with a focus on precision, efficiency, and quality. Equipped with advanced CNC machines and skilled engineers, we provide accurate parts for industries ranging from automotive to electronics. In addition to CNC machining, HRC offers comprehensive manufacturing services including sheet metal fabrication,welding, bending, and laser cutting. This diverse capability allows us to deliver complete solutions, from prototypes to large-scale production, all under one roof. With strict quality control and fast turnaround.

At HRC, we are committed to offering not only products but also complete manufacturing solutions. Our goal is to help clients achieve better designs, faster delivery, and long-lasting performance.

Huaruicheng Introduction Video

As a one-stop rapid manufacturing and prototyping company for your team, let’s watch the video to learn more about how Huaruicheng MetalManufacturing supports on-demand parts production and custom manufacturing.

Huaruicheng Manufacturing Capabilities

rapid prototyping

From design to prototyping and all the way to production, Huaruicheng Metal is always dedicated to turning your ideas into reality.

CNC Machining

We use CNC machines, which are crucial in our manufacturing process. Reliable CNC machining for high-performance applications

Sheet Metal

Sheet metal process involving cutting, bending, welding, and forming of metal sheets to custom components for various industries.

Die casting

Die casting is a process that uses reusable metal molds to produce complex, dimensionally accurate metal parts in large quantities.

Our CNC Machining Capabilities

Our CNC Machining Capabilities encompass advanced milling, turning, and multi-axis operations, delivering exceptional precision for complex components. We expertly process diverse materials—including aluminum, steel, titanium, and engineering plastics—with tight tolerances as low as ±0.001mm. From rapid prototyping to high-volume production, our skilled equipment and skilled technicians ensure consistent quality, meeting stringent industry standards for automotive, aerospace, and medical sectors.

CNC Lathe Machining

Our CNC turning centers produce precise cylindrical and threaded components with high efficiency, ideal for shafts, pins, and connectors.

CNC Milling Machining

We offer 3- to 5-axis CNC milling to create complex geometries, pockets, slots, and surface profiles.

CNC Drilling Machining

CNC Drilling Machining is computer-controlled precision hole-making in diverse materials with tight tolerances for industries.

Machinable Materials

Choosing the right material is a key factor in CNC machining. Different materials offer unique mechanical properties, machining performance, and application suitability. At HRC, we work with a wide range of metals and plastics to meet diverse industry needs. Below we highlight the most commonly machined materials.

Aluminum is one of the most popular materials in CNC machining due to its excellent machinability, lightweight nature, and corrosion resistance. It offers good strength-to-weight ratio and is widely used in automotive, aerospace, electronics, and consumer goods. Common grades include 6061, 7075, and 2024, each serving different strength and performance requirements.

Stainless steel provides high strength, excellent corrosion resistance, and good heat resistance, making it ideal for demanding environments. It is commonly used in medical devices, food processing equipment, aerospace components, and marine parts. While harder to machine than aluminum, stainless steel ensures durability and long service life. Popular grades include 304, 316, and 416 stainless steel.

Brass, copper, and bronze are widely used in CNC machining for their superior electrical and thermal conductivity, corrosion resistance, and aesthetic appeal.

Brass: Easy to machine, excellent for precision parts and decorative components.

Copper: Best for electrical components and heat exchangers due to high conductivity.

Bronze: Offers excellent wear resistance and is used for bearings, bushings, and marine applications.

Plastics such as POM (Delrin), Nylon, PTFE, and ABS are frequently machined for lightweight, cost-effective solutions. They offer excellent chemical resistance, electrical insulation, and design flexibility, making them popular in electronics, automotive interiors, medical devices, and consumer products.

We have our own anodizing factory. After the first proofing, we can effectively guarantee that the subsequent products will have no color difference problems. We can also customize the color in small quantities without MOQ.

- Self Anodize Factory

- Keep The Same Color

- Custom Pantone Color

- No MOQ To Custom

Surface Treatment

To ensure your CNC machined parts perform reliably and look professional, HRC provides a variety of surface treatments and post-processing services. These finishing options enhance strength, resistance, appearance, and functionality. Depending on your requirements, we can offer anodizing, blasting, coating, heat treatment, and polishing to bring out the best in every component.

Anodizing and Hard Anodizing

Anodizing improves the corrosion resistance, hardness, and wear resistance of aluminum components while also providing aesthetic finishes in different colors. Hard anodizing further enhances surface durability, making it ideal for aerospace and automotive parts exposed to extreme conditions.

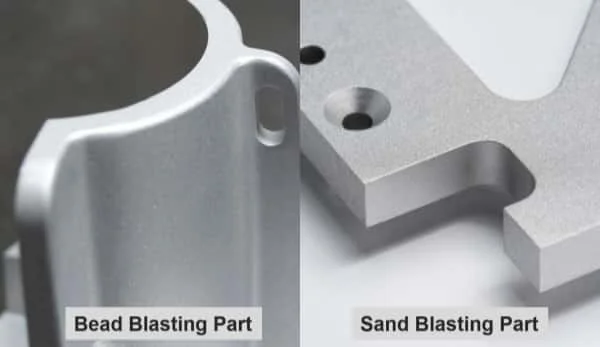

Sandblasting and Bead Sanding

Sandblasting and bead blasting create smooth, matte finishes by removing tool marks and surface imperfections. This process improves both the appearance and adhesion of coatings, making it a popular option for consumer electronics and decorative components.

Spraying Coating and Power Coating

Protective coatings and lacquers not only improve the visual appeal of machined parts but also add functional benefits such as scratch resistance, corrosion protection, and chemical resistance. We offer both functional and decorative coating solutions to meet client requirements.

Heat Treatment and Polishing

Heat treatment enhances the mechanical properties of metals, improving hardness, strength, and durability. Polishing provides a smooth, reflective surface finish suitable for medical and decorative applications. Together, these processes ensure optimal performance and aesthetics.

How to Customize A Product?

Whether you have a fully formed concept or just a basic idea, send us your artwork – a drawing, photo, or even a quick sketch. We’ll put in the effort to bring your design to life.

Design Confirmation

Provide ideas or 3D/2D drawings and your samples to us

Materials Selection

Choose the material according to the performance you want.

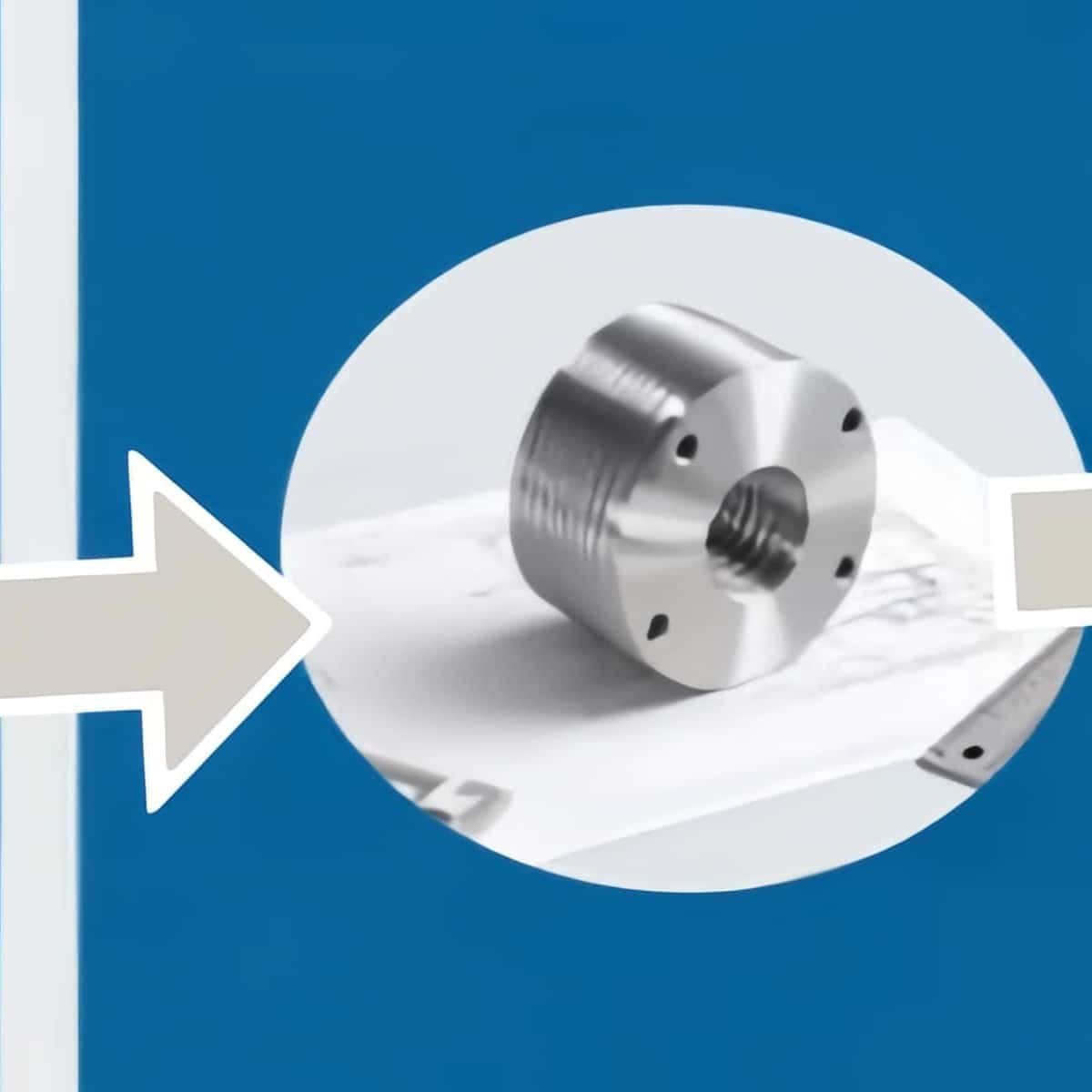

Making Production

Determine the processing method according to the structure

Surface Treatment

Generally choose Anti-UV anodize to prevent discoloration

Package Delivery

Use custom foam to protect the product from scratches during transportation

One-stop customized service

We provide one-stop customized machining services, from material selection, design consultation, and CNC programming to precision machining, surface finishing, and final assembly. This integrated approach eliminates the need for multiple suppliers, reduces communication costs, and shortens lead times. Whether it’s a single prototype or a high-volume production run, our team ensures seamless coordination across every stage of the project. Customers benefit from streamlined workflows, consistent quality, and flexible solutions tailored to their exact specifications.

Design

Production

Sample

Package

Why Choose with Us?

Partnering with HRC means working with a manufacturer who values quality, precision, and reliability. We offer decades of machining experience, engineering expertise, and integrated services that reduce the complexity of sourcing from multiple vendors. With competitive pricing, global delivery, and ISO-certified processes, we are a trusted choice for businesses worldwide.

Experienced Engineering Team

Our engineering team brings together years of expertise in CNC machining, product design, and manufacturing optimization. They not only understand the technical aspects of machining different materials but also excel in providing practical design-for-manufacturing (DFM) advice. This ensures your parts are produced with maximum efficiency, reduced costs, and reliable performance. From solving complex technical challenges to advising on tolerance requirements, our engineers act as trusted partners, working closely with you to achieve the best results.

Rigorous Inspection Processes

Every component we produce undergoes a strict and systematic inspection process. We implement first-article inspection (FAI), in-process quality checks, and final 100% inspection before delivery. By adhering to ISO and international quality standards, we make sure that every product leaving our factory is defect-free and matches customer specifications. This disciplined approach to quality control reduces the risk of errors, enhances reliability, and guarantees consistent results across small or large production runs.

Advanced Testing Equipment

We are equipped with a wide range of advanced inspection and testing instruments, including CMMs (Coordinate Measuring Machines), hardness testers, surface roughness testers, and digital calipers. These tools enable us to achieve and verify tight tolerances with exceptional accuracy. Our ability to measure complex geometries and validate material performance ensures that every product not only meets industry standards but also exceeds customer expectations. With this advanced equipment, we deliver dependable solutions for industries that demand the highest precision, such as aerospace, automotive, and medical devices.

Industries Huaruicheng Metal Service

Applicable to multiple industries

Aerospace Industry

Lightweight, high-strength, and tight-tolerance parts are produced for aerospace applications,please contact us.

Medical Industry

We supply precision-machined components for surgical instruments, medical devices, and diagnostic equipment.

Automotive Industry

We manufacture engine parts, transmission components, and custom prototypes that meet industry standards.

Consumer Electronics

Our services support electronics with custom housings, heat sinks, and structural parts,if you have any qustions,please contact us.

What does CNC stand for?

what makes us different

CNC machines

CNC milling machine, often simply referred to as a CNC mill. It uses rotating multi-point cutting tools to remove material from a workpiece, creating complex shapes and features. CNC mills can work with various materials, including metals, making them a staple in CNC metal machining.

Online CNC services

The advent of the internet has also brought about Online CNC Services. These services allow users to upload their design files, receive quotes, and have their parts manufactured. Online CNC service providers have a network of CNC machines that can quickly turn around projects.

Rapid Prototyping

Huaruicheng Metal is your reliable R&D partner. It is faster than ever, from a CAD design to a prototype in your hands, and finally to your team. Our rapid prototyping services include CNC prototyping, 3D printing, vacuum casting, rapid tooling, sheet metal prototyping, and prototype finishing.

CNC metal machining

In metal working, CNC metal machining enables the production of high-tolerance parts for aerospace, automotive, and electronics industries. Manufacturers no longer have to rely solely on skilled manual labor for intricate tasks. With CNC machines, the margin of error is significantly reduced, leading to higher-quality products.

CNC machining shop

Searching for "CNC near me" has become easier, as online directories and service platforms can connect customers with local CNC machining shops. Whether it's for prototyping or large - scale production, the online aspect of CNC services has made the technology more accessible and convenient for a broader range of users.

Rapid Manufacturing

Huaruicheng Metal is also your best manufacturing partner. We offer a range of solutions to help you scale from effective prototypes to production parts. Our rich manufacturing experience and ability to integrate resources enable us to handle any project’s needs and ensure your parts always meet the highest quality standards.

CNC Machining Cases

To demonstrate our expertise, HRC provides case studies that showcase real projects. These examples highlight our ability to meet unique challenges while maintaining superior quality and efficiency.If you also want to customize some of your products at this moment, please click the button below to contact us. Thank you

Huaruicheng Certifications

Our company holds a series of prestigious international certifications that demonstrate our unwavering commitment to quality, safety, and regulatory compliance.

These include the FDA registration, which confirms our adherence to strict standards for products in the regulated US market. We are also certified to ISO 9001:2015, ensuring our Quality Management System meets the highest global benchmarks for consistency and customer satisfaction.

Furthermore, our products are verified by SGS, the world’s leading testing, inspection, and certification company, providing independent assurance of their quality and reliability. These certifications collectively underscore our dedication to excellence and building trust worldwide.

Let's work together!

We would love to speak with you.

Feel free to reach out using the below details.