High-Precision CNC EDM Services

Whether you’re working with ultra-hard materials, intricate geometries, or delicate components,

our advanced EDM technology guarantees results that traditional machining simply cannot achieve.

- Produces smooth and refined surface quality

- Capable of cutting extremely tough materials

- Applies zero mechanical force on fragile components

What is CNC EDM?

Electrical Discharge Machining (EDM) is a non-traditional manufacturing process that uses electrical sparks to erode material from a workpiece. Instead of relying on physical cutting forces, EDM removes material through controlled electrical discharges between an electrode and the workpiece, submerged in a dielectric fluid.

- How CNC control enhances precision and repeatability

With CNC integration, EDM machines can execute highly complex cutting paths with extreme accuracy. This allows for consistent results across multiple parts, maintaining tight tolerances and superior surface finishes.

- When to choose EDM vs. traditional CNC machining

EDM is particularly advantageous when machining hardened materials, creating intricate internal features, or achieving sharp corners and fine details that conventional milling or turning cannot accomplish. It is the preferred choice for tooling, aerospace, and medical components where precision is critical.

Types of CNC EDM We Offer

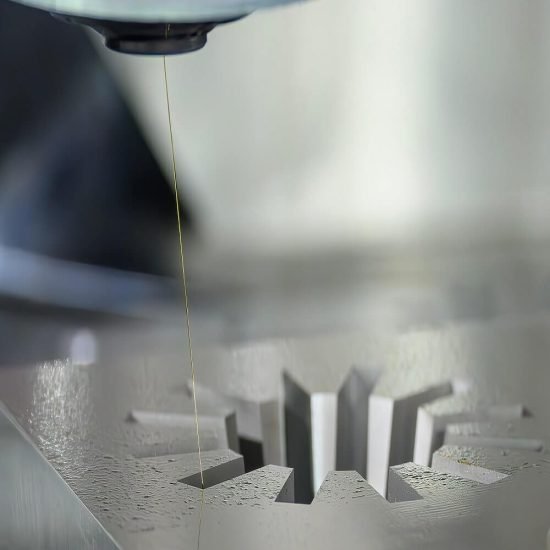

Wire EDM

Wire EDM services, also called “Wire Cut EDM”, uses a thin, electrically conductive wire (typically brass, copper, or tungsten, with diameters as small as 0.02mm) as the electrode. The wire is fed continuously through the workpiece, and sparks erode the material along the wire’s path—similar to a “thermal saw.” Ideal for cutting 2D and 3D shapes (e.g., dies, punches, gears) in thick or hard materials.

Sinker EDM

Sinker EDM, also known as “Ram EDM”, uses a custom-shaped electrode (usually made of copper, graphite, or copper-tungsten) to create cavities, pockets, or 3D shapes in the workpiece. The electrode is “sunk” into the workpiece—either by moving the electrode toward the workpiece or vice versa—and sparks erode the material to match the electrode’s form.

EDM Drilling

EDM Drilling, also called “EDM Deep Hole Drilling”, is specialized for creating small, deep holes, often with high aspect ratios-depth-to-diameter ratios of 100:1 or more, in hard materials. It uses a tubular electrode (typically copper or brass) through which dielectric fluid is pumped to flush away eroded material.

Advantages of CNC EDM

CNC EDM offers unique benefits that make it the preferred choice for hard-to-machine materials and complex designs:

Machines extremely tough materials – Processes hardened steels, titanium, tungsten carbide, and other alloys with ease.

High accuracy and consistency – Achieves tolerances up to ±0.002 mm for precise and repeatable results.

Complex geometries – Enables sharp corners, micro-holes, and intricate cavities beyond conventional machining limits.

Excellent surface finishes – Produces smooth surfaces down to Ra 0.1 μm, often reducing the need for secondary finishing.

No mechanical stress – Spark erosion applies no cutting force, protecting thin-walled and delicate components.

| Feature | CNC EDM | Traditional Machining |

|---|---|---|

| Material Hardness Limitations | No limitations (conductive materials only) | Limited by tool hardness |

| Geometric Complexity | Virtually unlimited | Limited by tool access |

| Surface Finish | Excellent to mirror-like (2-32 μin Ra) | Good to excellent |

| Tolerances | ±0.0001" achievable | ±0.001" typical |

| Setup Time | High (but excellent for complex parts) | Moderate to high |

| Production Speed | Slow to moderate | Fast |

| Tool Wear | Minimal (non-contact process) | Significant (especially with hard materials) |

| Burr Formation | Minimal | Significant (requires secondary operations) |

Materials for CNC EDM

One of EDM’s strengths is its ability to machine electrically conductive materials regardless of hardness. Unlike traditional machining, there is no need to soften or anneal materials prior to processing. This enables faster turnaround and preserves the material’s original properties.

The table below clearly shows the difference in the selection of processing materials for CNC EDM and traditional machining processes:

| Material Type | CNC EDM | Traditional Machining |

|---|---|---|

Hardened Steel (>45 HRC) | ||

Titanium Alloys | ||

Tungsten Carbide | ||

Aluminum | ||

Inconel & Superalloys | ||

Polycrystalline Diamond (PCD) |

CNC EDM Applications

CNC EDM is utilized across various industries for precision manufacturing needs:

- Mold and Die Components:

Injection molds, die-casting dies, stamping dies, extrusion dies

- Medical Devices:

Surgical instruments, implants, orthopedic devices, micro-components for medical equipment

- Aerospace Components:

Turbine blades, engine components, fuel system parts, lightweight structural components

- Automotive:

Prototyping and production parts, fuel injection components, transmission parts, sensors

- Electronics:

Semiconductor components, micro-connectors, fabrication tools, heat sinks

- Prototyping:

Rapid prototyping for design validation and functional testing

- Metal Disintegration:

Removal of broken tools and fasteners without damaging the parent material

Our CNC EDM Capabilities

With advanced multi-axis EDM equipment and years of process expertise, we deliver machining solutions that meet the highest industry standards:

Wire EDM – For high-precision cutting of complex profiles, fine details, and sharp corners.

Sinker EDM – For creating cavities, deep slots, and custom-shaped impressions.

EDM drilling – For micro-holes, cooling channels, and deep, narrow holes with excellent straightness.

Extreme precision – Tolerances up to ±0.002 mm for critical components.

Surface finishes – As fine as Ra 0.1 μm, minimizing the need for polishing.

Flexible production – From prototypes and one-off parts to high-volume production runs.

Industry compliance – Adherence to aerospace, automotive, and medical machining standards.

Post-Processing & Finishing Options

To ensure your parts meet both functional and cosmetic requirements, we provide a range of value-added finishing and support services:

Polishing

Our polishing services improve the surface finish by removing micro-imperfections and sharp edges. This results in smoother surfaces that are not only visually appealing but also reduce friction and wear in functional applications. For medical and aerospace parts, a fine polish ensures compliance with hygiene and performance standards.

Heat Treatment

Many EDM-machined components require enhanced mechanical properties after fabrication. We provide controlled heat treatment processes to increase hardness, strength, and wear resistance. This step is especially valuable for tooling, dies, and components exposed to heavy loads or abrasive environments.

Coating & Surface Protection

We offer a variety of protective coatings, including anodizing, plating (nickel, chrome, or zinc), and specialized coatings designed for corrosion resistance or electrical insulation. Surface treatment ensures components perform reliably in harsh environments while extending their operational lifespan.

Assembly Support

For customers requiring more than just standalone parts, we provide assembly support services. This includes fitting EDM-machined components into larger mechanical systems, sub-assemblies, or tooling setups, reducing your production workload and ensuring compatibility with final applications.

CNC EDM FAQs

What is a CNC EDM drill and when is it used?

A CNC EDM drill (also called hole drilling EDM) is used to quickly produce very small and deep holes in hard materials, often serving as starter holes for wire EDM operations.

What industries commonly use hole drilling EDM?

Hole drilling EDM is widely used in aerospace, medical, mold-making, and energy industries for producing cooling holes, micro-holes, and other features in materials that are otherwise difficult to machine.

What is a CNC EDM machine and how does it work?

A CNC EDM machine (Electrical Discharge Machine) uses electrical sparks to remove material from conductive metals with extreme accuracy. It is ideal for creating complex shapes, tight tolerances, and high-quality surface finishes.

How does wire EDM wire affect cutting performance?

The choice of wire EDM wire (brass, coated, or molybdenum) impacts cutting speed, surface finish, and accuracy. Selecting the right wire ensures better efficiency and part quality.

What applications are suitable for CNC EDM wire cut?

CNC EDM wire cut is commonly used for manufacturing dies, punches, gears, aerospace components, and precision parts that require sharp corners and intricate profiles.

What materials can be processed using CNC wire EDM?

CNC wire EDM can cut very hard materials like tool steel, tungsten carbide, titanium, and hardened alloys that are difficult to machine with conventional methods.

What is a sinker EDM machine and how is it different from wire EDM?

A sinker EDM machine (also known as EDM sinker) uses a shaped electrode that sinks into the workpiece to form cavities or complex 3D shapes, whereas wire EDM cuts profiles with a continuously fed wire.

What is the difference between EDM CNC and traditional machining?

Unlike traditional cutting tools, EDM CNC processes use electrical discharges instead of mechanical force, meaning there is no stress on the part and intricate shapes can be achieved with excellent precision.