Precision CNC Machining Services: Custom Parts & Prototyping

Experience the best online CNC service for rapid CNC prototyping and production.

Get an instant quote for your custom metal or plastic parts today.

- Achieve tolerances as tight as ±0.025 mm (±0.001″).

- ISO 9001:2015 certified quality management system.

- Machine over 80+ metal and engineering plastic materials.

Trusted By

What Is CNC Machining?

Definition of CNC (Computer Numerical Control)

CNC, or Computer Numerical Control, refers to the technology that uses computer programs to control the movement and operation of machine tools. These programs translate design specifications into numerical code (most commonly G-code), which directs the machine’s axes, tool speed, cutting depth, and other critical parameters. By replacing manual control with computerized precision, CNC machining eliminates human error, reduces production time, and ensures uniform quality across every part—even for highly complex geometries.

How Does CNC Machining Work?

CNC machining follows a structured, four-step process to transform digital designs into physical parts. Each step is critical to ensuring accuracy, efficiency, and adherence to your design requirements.

Step 1: CAD Design Preparation

Start with a 2D/3D CAD model defining geometry, tolerances, and critical features. Preferred formats: STEP, IGES, Parasolid, and native CAD such as SolidWorks. Include a PDF drawing for GD&T, threads, and finishes.

Step 2: Converting CAD to CNC Program (G-code)

CAM software generates toolpaths and posts G-code specifying tool type, spindle speed (RPM), feed rate, coolant, and coordinate moves. Simulation checks collisions and cycle time before machining.

Step 3: Machine Setup & Tool Selection

We select cutters based on material and feature: carbide end mills for aluminum and steels, indexable inserts for turning, high-precision drills and reamers for holes. Fixtures and soft jaws ensure rigidity and repeatability.

Step 4: Precision Cutting & Finishing

Roughing removes bulk material; finishing passes achieve final dimensions and surface finish (e.g., Ra 1.6–3.2 μm typical, lower with grinding or polishing). Post-machining services include deburring, anodizing, powder coating, passivation, and plating.

Types of CNC Machining Process

We offer a full range of CNC machining processes to address diverse part geometries, materials, and industry needs. Below are the most common services we provide:

CNC Milling Service

Our 3 axis, 4 axis, and 5 axis milling machines can create flat surfaces, slots, pockets, and complex 3D shapes. We offer precision CNC machining for complex metal and plastic parts and ensure accurate tolerances. Our key capabilities include:

- Tolerances: ±0.0005 inches for critical features, with positional accuracy of ±0.0002 inches per foot.

- Ideal for: Parts with intricate details, such as gears, enclosures, custom fasteners, and mold inserts.

- Software integration: Compatible with all major CAD/CAM formats, including STEP, IGES, STL, and DWG.

CNC Turning Services

Our turning centers are equipped with live tooling, allowing for milling, drilling, and tapping operations in a single setup, reducing lead time and improving accuracy. High-precision lathes produce shafts, bushings, and threaded components. Common applications include:

- Threaded components (e.g., bolts, nuts).

- Parts with symmetric geometries.

- Our turning centers support spindle speeds up to 8,000 RPM, and deliver tolerances as tight as ±0.0002 inches.

CNC Drilling Services

Specializes in creating precise holes in workpiece materials using rotating drill bits with exact positioning and depth control.

Using high-speed drills or end mills ensures consistent hole diameter, depth, and positioning—even for parts with hundreds of holes. We offer:

- Hole sizes: From 0.01 inches to 2 inches, with depth-to-diameter ratios up to 15:1 for deep-hole drilling.

- Tapping capabilities: Up to 1″ thread size with thread depths up to 3× diameter.

- Compatibility with all metals and plastics, including brittle materials like glass-filled plastics.

CNC Grinding Services

CNC grinding uses abrasive wheels to refine the surface finish and dimensional accuracy of parts, particularly those requiring ultra-smooth surfaces or tight tolerances. It is often used as a finishing step for hard metals or parts where precision is critical. Our grinding services include:

- Surface grinding: For flat surfaces, with parallelism tolerance of ±0.0001 inches over 12 inches.

- Cylindrical grinding: For round parts, with a roundness tolerance of 0.00005 inches.

- Centerless grinding: For high-volume cylindrical parts like shafts, with consistent diameter control.

EDM CNC

EDM (Electrical Discharge Machining) uses electrical sparks to erode material from the workpiece—ideal for hard-to-machine materials or complex geometries that cannot be cut with traditional tools. We offer two types of EDM:

- Wire EDM: Uses a thin metal wire to cut intricate shapes with tolerances of ±0.0001 inches.

- Sinker EDM: Uses a custom electrode to create cavities or internal features with surface finishes down to Ra 0.05 μm.

- Advantages: No cutting forces, so delicate parts remain undamaged; capable of machining materials up to 65 HRC.

5 Axis CNC Machining Services

5-axis CNC machining allows the machine to simultaneously move the workpiece or tool along five axes. This capability eliminates the need for multiple setups, reduces production time, and enables the creation of highly complex, 3D geometries. Key benefits include:

- Machining of undercuts, angled holes, and curved surfaces in one operation, reducing setup time by up to 50% vs. 3-axis machining.

- Improved surface finish: Continuous tool contact with the workpiece minimizes tool marks and improves surface quality.

- Tighter tolerances: ±0.0003 inches due to fewer setups.

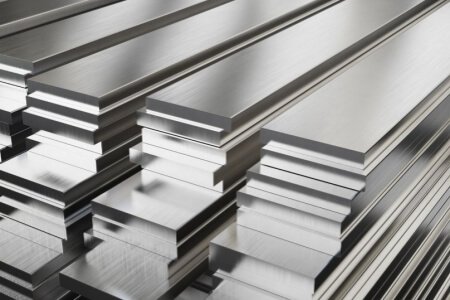

CNC Machining Materials

We work with a wide range of metals and plastics to match your part’s functionality, durability, and cost requirements. Our team helps you select the optimal material based on your application.

Aluminum Alloy

Lightweight (1/3 the density of steel) with excellent machinability, corrosion resistance, and thermal conductivity. Ideal for aerospace components, automotive parts, and consumer electronics (e.g., laptop frames).

Stainless Steel

Offers exceptional corrosion resistance, strength, and durability. Suitable for medical devices, food-processing equipment, and marine parts. Grades like 304 and 316 are widely used.

Steel

High-strength and cost-effective, with good wear resistance. Used for industrial machinery components, tooling, and automotive structural parts. Common grades: 1018 and 4140.

Titanium Alloy

Ultra-strong, lightweight, and biocompatible—perfect for medical implants, aerospace parts, and high-temperature applications. Grade 5 (Ti-6Al-4V) is the most popular, though it requires specialized machining due to its hardness.

Brass

Excellent machinability, electrical conductivity, and aesthetic appeal. Used for electrical connectors, plumbing fittings, and decorative parts. It is non-magnetic and offers good corrosion resistance in non-harsh environments.

Magnesium Alloy

The lightest structural metal, even lighter than aluminum with high strength-to-weight ratio. Ideal for aerospace, automotive, and electronics where weight reduction is critical. Requires careful handling due to flammability during machining.

ABS

A durable, low-cost thermoplastic with good impact resistance. Used for consumer goods, enclosures, and prototypes. It is easy to machine and can be painted or bonded for customization.

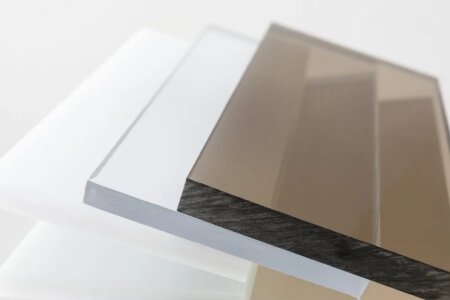

Polycarbonate (PC)

Transparent, shatter-resistant, and heat-tolerant (up to 135°C). Suitable for optical components, safety guards, and medical devices (e.g., clear housings). It maintains strength in harsh environments.

POM

Also known as acetal, POM is rigid, low-friction, and resistant to chemicals and wear. Used for gears, bearings, and precision mechanical parts (e.g., zip fasteners) where smooth movement is key.

Nylon

A flexible, wear-resistant thermoplastic with high tensile strength. Ideal for parts requiring durability and impact resistance, such as bushings, washers, and automotive connectors. It also has good resistance to oils and fuels.

PEEK

A high-performance thermoplastic with exceptional heat resistance (up to 260°C), chemical resistance, and biocompatibility. Used for aerospace components, medical implants (e.g., spinal fusion devices), and industrial parts in extreme environments.

CNC Machining Surface Finish

As Machined + Deburring

As machined parts are delivered without additional finishing, ensuring dimensional accuracy. Deburring removes sharp edges for safety, making this a cost-effective solution for functional prototypes and internal components without aesthetic requirements.

Bead Blasting

Bead blasting uses fine glass beads under high pressure to create a smooth, uniform matte surface. This process hides machining marks, enhances coating adhesion, and gives aluminum or stainless steel parts an elegant, refined appearance.

Anodizing

Anodizing creates a protective oxide layer on aluminum parts, improving wear resistance and allowing vibrant color options. This finish offers excellent corrosion protection and a premium look, commonly used in aerospace, electronics, and consumer product applications.

Electroplating

Electroplating deposits a thin metal coating, such as nickel or chrome, to enhance corrosion resistance and appearance. It’s widely applied to steel and brass components for durability and aesthetics in automotive, electrical, and decorative product applications.

Electrochemical Polishing

Electropolishing removes a thin metal layer through an electrochemical process, producing a mirror-like finish. This improves corrosion resistance, cleanliness, and surface hygiene, making it ideal for stainless steel and medical components requiring a high-quality appearance.

Brushed Finish

Brushing uses abrasive belts to create fine linear patterns on metal surfaces, delivering a satin-like appearance. It’s popular for decorative components and appliances, reducing glare while masking minor imperfections for an attractive, uniform surface finish.

Powder Coating

Powder coating applies electrostatically charged powder and cures it under heat for a thick, durable finish. It provides excellent impact and chemical resistance with a wide range of colors, making it ideal for machinery and outdoor metal components.

Custom Laser Engraving

Laser engraving uses a focused beam to create permanent markings such as logos, text, or serial numbers. It provides high-contrast, durable identification without damaging the part, suitable for branding and traceability across metals and some plastics.

Applications Across Industries

Automotive Parts Manufacturing

Compliant with IATF 16949, we supply parts for traditional and EVs: engine components (pistons/camshafts), transmission gears (4140 steel), EV battery housings (6061-T6 aluminum), and custom chassis brackets. We scale from prototypes to high-volume production.

Consumer Electronics Products

We deliver small, precise parts with fast turnaround: smartphone frames (aluminum), laptop hinges/heat sinks (copper/aluminum), smartwatch cases (titanium/ABS), and audio components (brass/plastic). Services include rapid prototyping (3–5 days) and high-volume production with branding finishes.

Aerospace Components

We manufacture ultra-precise parts for aerospace, adhering to AS9100 and FAA/EASA standards. Key products: turbine blades (titanium/Inconel), airframe brackets (7075 aluminum), fuel system components (316 stainless), and EMI-shielded avionics enclosures.

Medical Device Production

Operating in class 10,000 cleanrooms (FDA 21 CFR Part 820, ISO 13485), we make biocompatible parts: surgical instruments (440C steel), hip/knee implants (titanium/PEEK), diagnostic sensor housings, and dental crowns/abutments. Full traceability and sterile packaging are available.

Benefits of CNC Machining

High Accuracy & Tight Tolerances

CNC machines operate with computerized precision, eliminating human error and ensuring parts meet even the strictest dimensional requirements. With advanced calibration tools and 5-axis capabilities, we achieve tolerances as tight as ±0.0001 inches.

Fast Turnaround & Repeatability

CNC machining automates most of the production process, reducing setup time and cutting cycles. For prototypes, we can deliver parts in as little as 3-5 business days; for high-volume production, our machines run 24/7 to meet tight deadlines. Additionally, CNC programs are easily stored and reused, ensuring every part in a batch is identical.

Cost-Effectiveness for Complex Parts

While CNC machining has higher upfront costs, it becomes highly cost-effective for complex parts or large production runs. Automated machines require minimal human oversight, lowering labor expenses. Precise cutting reduces scrap material, especially for expensive metals like titanium. High accuracy means fewer defective parts, eliminating the cost of reworking or scrapping components.

Our CNC Machining Capabilities & Equipment

At HRC CNC, we combine advanced machinery with expert engineering to deliver high-precision CNC machining services for a wide range of industries. Our in-house capabilities ensure accuracy, repeatability, and cost-efficiency for both prototype and production orders.

CNC Machines (3-Axis, 5-Axis)

We operate state-of-the-art CNC machines, including 3-axis and 5-axis machining centers, to handle complex geometries and tight tolerances.

- 3 axis cnc machining

Ideal for standard milling and turning operations, offering excellent precision for flat surfaces and simple contours.

- 5 axis cnc machining

Capable of machining multiple surfaces in a single setup, reducing cycle time and increasing accuracy for intricate components. Perfect for aerospace, automotive, and medical device parts where precision is critical.

Our advanced equipment allows us to machine parts with ±0.005mm tolerance, ensuring consistent quality across all projects.

Maximum Part Size Capacity

Our machining centers accommodate a wide range of part sizes:

- Maximum Milling Size: Up to 1200mm × 600mm × 500mm

- Turning Diameter: Up to 500mm

- Length Capacity: Up to 1500mm

This flexibility allows us to produce both small, intricate components and large, complex assemblies with ease.

FAQs About CNC Machining

What is your typical lead time?

For prototypes, our lead time is usually 3-5 days. Large production runs vary depending on complexity and quantity. With our CNC machining online quoting system, you can get instant estimates and faster turnaround times.

What materials can you machine?

We work with a wide range of materials for custom CNC machining, including metals like aluminum, steel, titanium, brass, and plastics like ABS, Nylon, and PEEK. Our aluminum CNC machining service is highly popular for lightweight and strong components.

What tolerances can you achieve?

Our high precision CNC machining services allow us to achieve tolerances as tight as ±0.005mm, ideal for industries that require exceptional accuracy such as aerospace, automotive, and medical devices.

Do you offer surface finishing services?

Yes, we provide various finishing options including anodizing, powder coating, plating, and polishing for your CNC parts, ensuring both performance and appearance meet your requirements.

Can you handle complex custom designs?

Absolutely! As a professional CNC machining manufacturer in China, we have advanced 3-axis and 5-axis machines to produce complex geometries with outstanding precision and repeatability.

Do you provide CNC machining services in China?

Yes! We are a leading CNC machining China service provider, offering reliable and cost-effective manufacturing solutions for global customers. Our competitive pricing makes us the best choice for both prototypes and mass production.

Is there an online platform for ordering CNC parts?

Yes, we provide a convenient CNC online service where you can upload your CAD files, select specifications, and receive instant quotes. This process makes ordering CNC parts easy and efficient.

Why choose your service for aluminum CNC machining?

Our aluminum CNC machining service ensures lightweight, durable, and precise components. We specialize in machining aluminum alloys for aerospace, automotive, and electronics applications, ensuring high-quality results every time.

Do you offer cheap CNC machining without compromising quality?

Yes, we provide cheap CNC machining solutions while maintaining strict quality control. By leveraging efficient processes and advanced equipment, we ensure affordability without sacrificing precision.

Request a Free Quote

Upload your CAD files or part drawings and receive an accurate quotation within 24 hours. Our experts will analyze your design and provide cost-effective suggestions to enhance manufacturability and reduce lead time.

Design Consultation Services

Need help refining your design? Our experienced engineers offer DFM (Design for Manufacturing) support to ensure your parts are optimized for CNC machining, reducing unnecessary costs and avoiding machining challenges.

Lead Time & Shipping Information

We guarantee fast turnaround times for prototypes (as quick as 3 days) and reliable shipping worldwide. All parts are securely packaged and tracked to ensure safe delivery to your location.

Email: Info@hrccnc.com

Phone: +86 17318068324

Our support team is available to assist you with material selection, tolerance requirements, and finishing options.